Expandable, fast, flexible

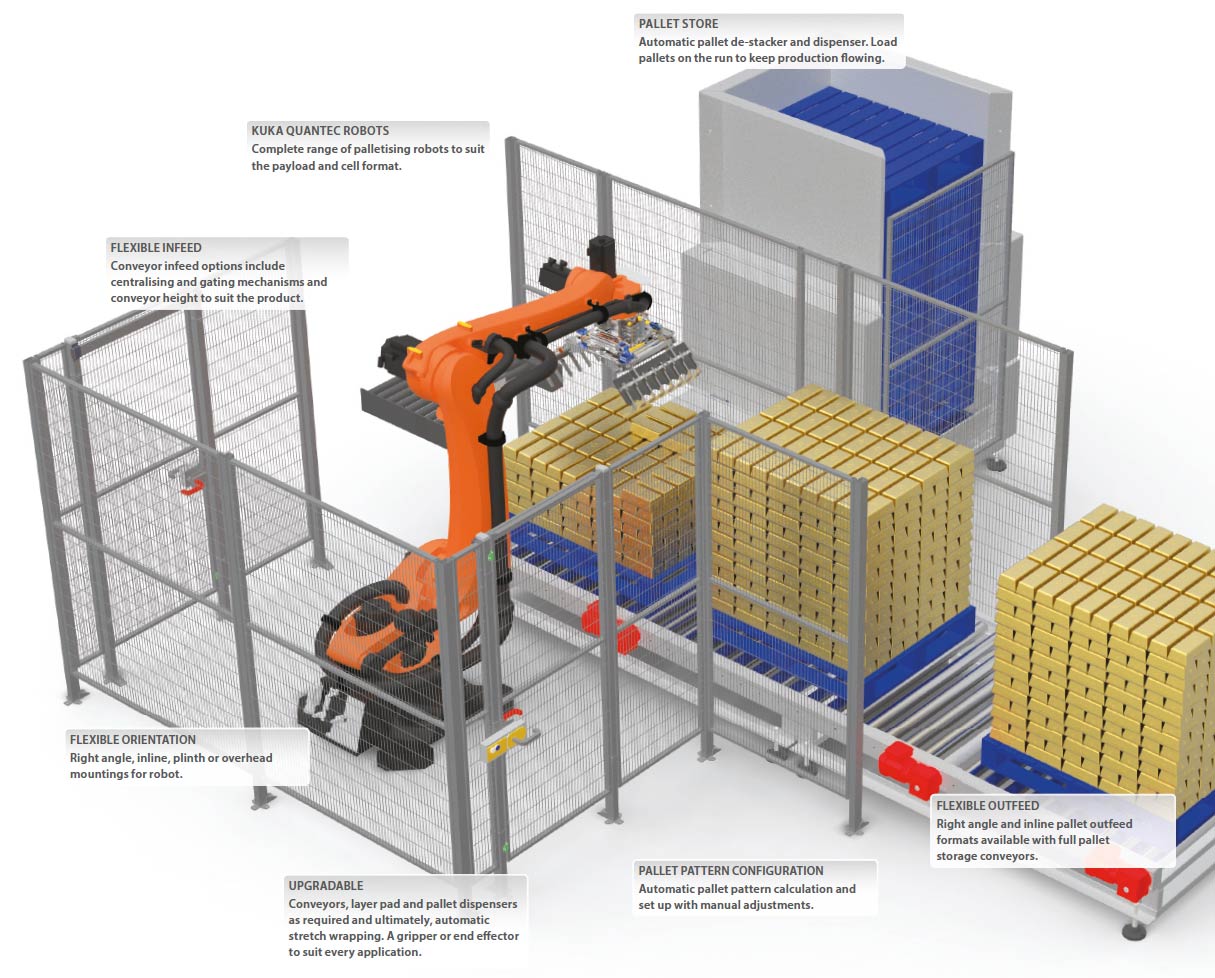

When selecting a robot palletiser system, the pallet pattern, product type, product orientation, product speed and system layout, will all be factors needing attention to suit the application.

A single cell robot can operate at up to 20 cycles per minute, depending on product and gripper selection.

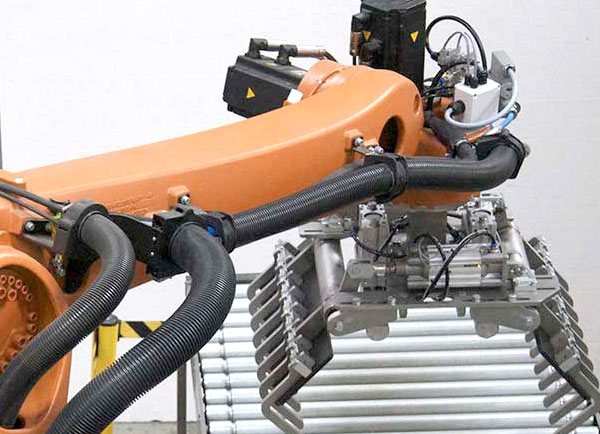

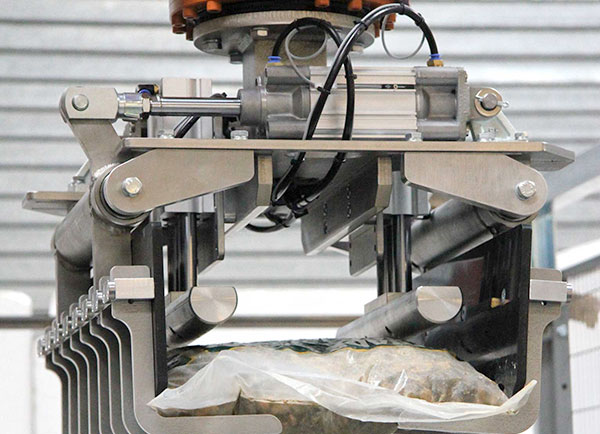

The products may be picked in multiples to achieve the required palletisation speeds in accordance with the pallet pattern. The basic gripper is a vacuum, rotating system, and other grippers are available.

Smart software and robotic factory automation maximises production while reducing costly downtime and repurposes labour.

Smart software and robotic factory automation maximises production while reducing costly downtime and repurposes labour.