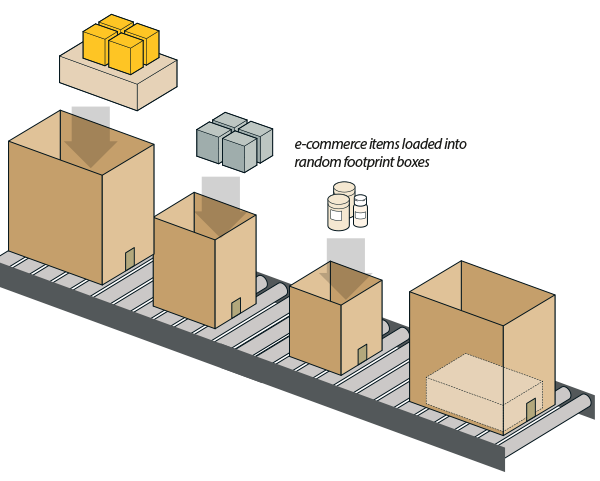

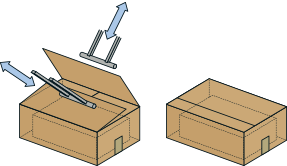

BoxSizer® eCommerce Smart Packaging Automation System is designed for warehouse dispatch fulfilment, where random, single, multiple, loose or grouped items or goods need to be packaged automatically into multiple footprint boxes for dispatch.

Smurfit Westrock Packaging Machinery & Automation multi-award winning BoxSizer is the only stand-alone ecommerce packing machine for multiple items that downsizes multiple footprint boxes, reducing volumetric dimensional weight (DIM weight), to save massively on Labour, Materials and Transportation costs.