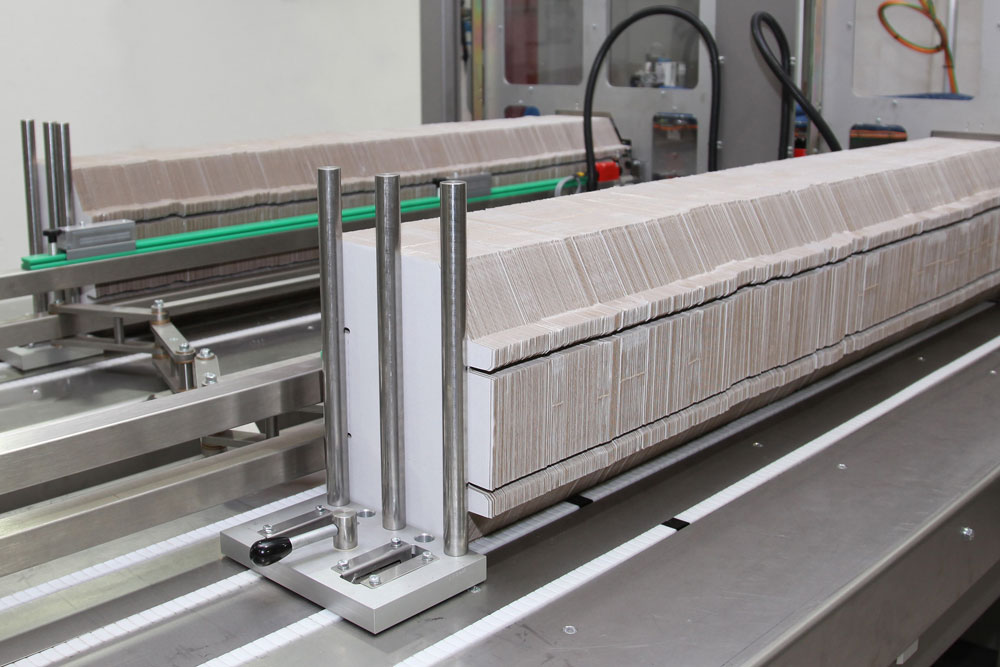

Smurfit Westrock PMA Tray Erector Range

Smurfit Westrock PMA range of Tray Erectors leave the competition behind. With an impressive output of up to 90 trays per minute.

Our innovative design offers; exceptional consistency, compact footprint, easy size change, outstanding speed, with an even faster payback.

Smart software and factory automation maximises production while reducing costly downtime and repurposes labour.

Plastic-free – Smurfit Westrock PMA Tray Erecting Machines can erect a wide range of trays, including tapered trays, using environment friendly, sustainable fluted card board materials making them ideal for reducing plastic packaging.