WestRock PMA Systems takes on a new challenge for one of Unilever’s ice cream factories to manufacture a bespoke robot pick and place system to increase packaging efficiency.

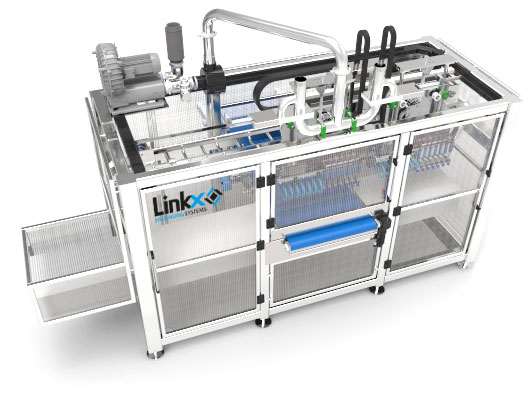

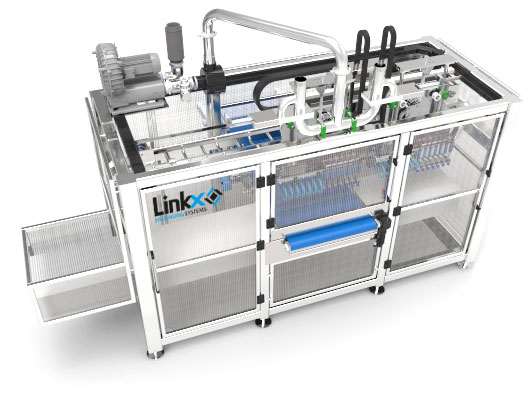

WestRock PMA have built a bespoke packaging automation robot pick and place and unloading system for Unilever’s Gloucester factory. The machine can pick and place up to 280 water-based products per minute helping to boost the lines speed and efficiency.

Unilever Gloucester wanted to reduce the amount of rejects from the case packer on their existing line, WestRock PMA automated solution was an intelligent robot pick and place machine.

The new robot pick and place system allows the product to be transferred from the multi-lane wrapper to the packer infeed belt in a uniform manner negating human intervention and increasing accuracy.

WestRock PMA took on the completely new project as a first and so based some of the common assemblies of their design on a similar, existing machine at Unilever’s Gloucester factory. This allows Unilever to keep common spares across their machine range.

The robot pick and place machine accepts an index of 14 uniform products from the multi-lane wrapper outfeed. Photoelectric sensors are then used to detect ‘double bags’ or empty products, with the possibility to integrate thermal imaging camera technology in the future.

The 4-axis servo-driven vacuum heads then picks and places the ‘good’ product onto an adjacent discharge conveyor and rejects the products that are missing. The control system utilizes Allen Bradley Kinetix 5500 range of servo drives and Compact Logix PAC, with full colour touch screen HMI for machine interface.

The robot pick and place machine is built from stainless steel, capable of running in 24-hour production environments and gives them a step in the right direction towards a more future-proof, smart factory. Factory automation is continually becoming a solution to increase efficiency.

Wall’s ice cream

Wall’s ice cream, a subsidiary of Unilever, has more than 80 years’ experience in the production of ice cream and iced products. They trusted WestRock PMA with taking on the challenge of building the pick and place system that is out of WestRock PMA’s standard range of machines.

WestRock PMA Systems are a packaging equipment manufacturer that designs and builds factory packaging automation solutions here in the UK. We focus on providing customers with packaging automation solutions for all types of businesses.

Talk to WestRock PMA today to find out how a bespoke packaging solution can improve your packaging automation 01502 713777 | contact

Unilever Gloucester wanted to reduce the amount of rejects from the case packer on their existing line, WestRock PMA automated solution was an intelligent robot pick and place machine.

The new robot pick and place system allows the product to be transferred from the multi-lane wrapper to the packer infeed belt in a uniform manner negating human intervention and increasing accuracy.

WestRock PMA took on the completely new project as a first and so based some of the common assemblies of their design on a similar, existing machine at Unilever’s Gloucester factory. This allows Unilever to keep common spares across their machine range.

Unilever Gloucester wanted to reduce the amount of rejects from the case packer on their existing line, WestRock PMA automated solution was an intelligent robot pick and place machine.

The new robot pick and place system allows the product to be transferred from the multi-lane wrapper to the packer infeed belt in a uniform manner negating human intervention and increasing accuracy.

WestRock PMA took on the completely new project as a first and so based some of the common assemblies of their design on a similar, existing machine at Unilever’s Gloucester factory. This allows Unilever to keep common spares across their machine range.

Wall’s ice cream, a subsidiary of Unilever, has more than 80 years’ experience in the production of ice cream and iced products. They trusted WestRock PMA with taking on the challenge of building the pick and place system that is out of WestRock PMA’s standard range of machines.

WestRock PMA Systems are a packaging equipment manufacturer that designs and builds factory packaging automation solutions here in the UK. We focus on providing customers with packaging automation solutions for all types of businesses.

Wall’s ice cream, a subsidiary of Unilever, has more than 80 years’ experience in the production of ice cream and iced products. They trusted WestRock PMA with taking on the challenge of building the pick and place system that is out of WestRock PMA’s standard range of machines.

WestRock PMA Systems are a packaging equipment manufacturer that designs and builds factory packaging automation solutions here in the UK. We focus on providing customers with packaging automation solutions for all types of businesses.