The Challenge

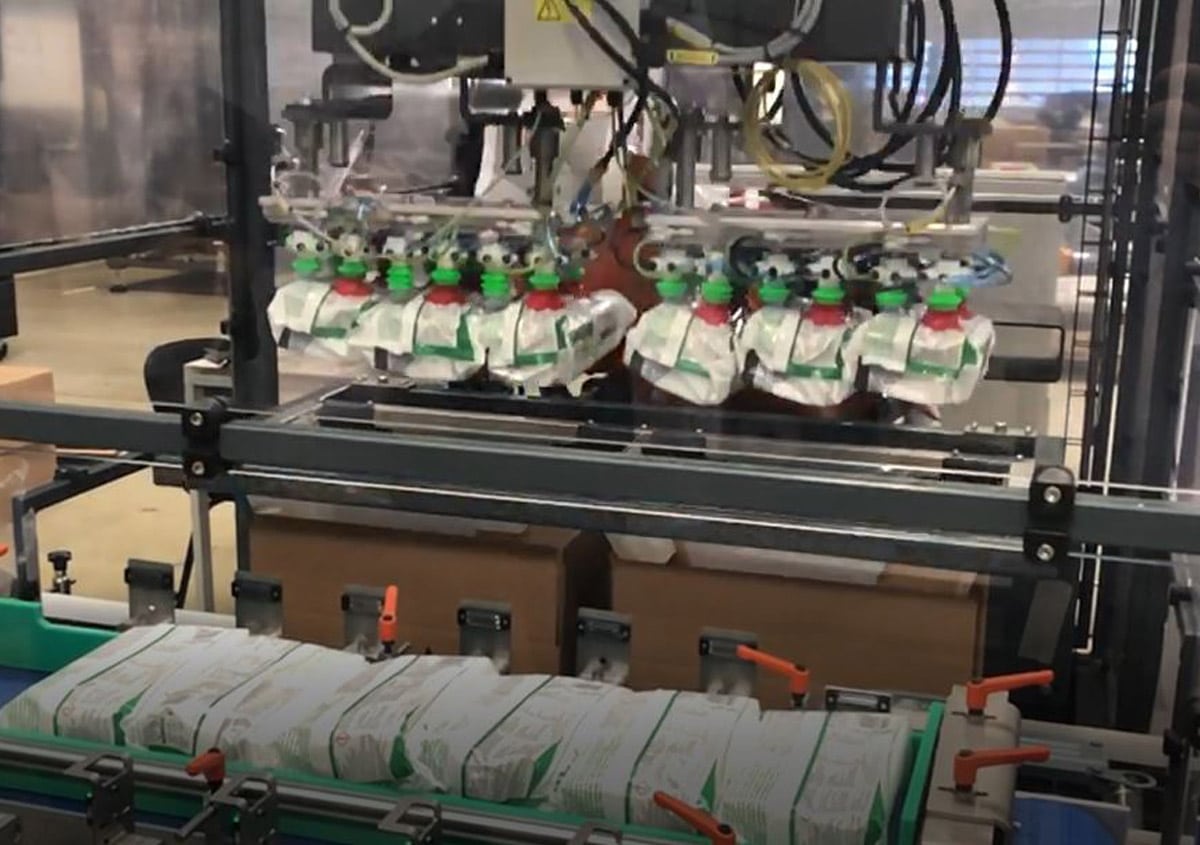

A UK-based market leader in the production of hygiene and infection control products urgently required an efficient end-of-line packaging system to meet the unprecedented demand posed by the onset of COVID-19.

They needed a solution that would comfortably meet the increased demand and be able to accommodate further line extensions/upgrades in the future. It also had to protect the integrity of the delicate medical cleaning products during the entire packaging and loading process, because they were exceptionally susceptible to damage. They also wanted to reduce labour costs as much as possible, and the solution had to fit within the space constraints of their new factory extension, which was currently under construction.

Our Solution

Despite unprecedented communication challenges caused by the nationwide lockdown, we pivoted to conduct thorough remote evaluations with the customer to understand their goals, constraints, timeframe and budgetary restrictions, as well as the very unique challenges of packaging their fragile product. As a result, we concluded that a multi-part solution of a case erector combined with a case loading robot would provide our customer with the optimal results they were looking for.

The Result:

- High spec multi-part system keeping fragile product safe

- Minimised packing labour costs

- Perfectly square, easy-to-stack cases, optimising pack presentation

- Easily upgradeable, future-proofed solution

- Minimal footprint