Food manufacturer increases speed and efficiency with integrated packaging lines

The Challenge

With the impending launch of a new product range, a leading UK manufacturer and supplier of edible oils and speciality ingredients to the food industry needed to improve efficiency and modernise their packing line process to reduce costs and meet increased demand. Their existing manual filling lines were slow and labour intensive, and the limited floor space was not being used to maximum advantage.

They required a solution that would replace their outdated filling process with a high-speed filling and automated packaging line, so they could accomplish faster packaging and loading to match their projected output. They also wanted to reduce labour, so that valuable human resources could be reassigned to other parts of the operation. Finally, the solution must have as minimal a footprint as possible.

Our Solution

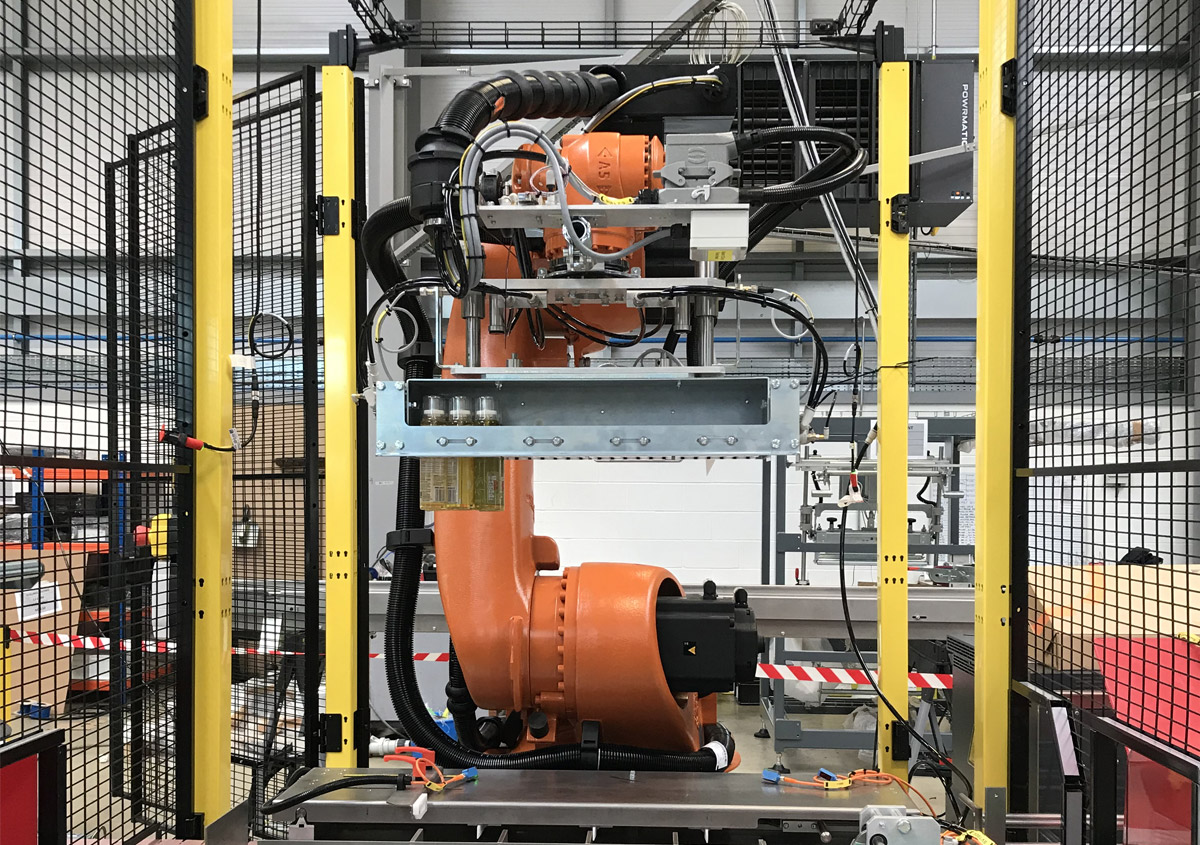

After assessing the limited space available and submitting a variety of layout proposals, a freestanding tray erector linked to a robot loader followed by a shrink wrapper was the chosen solution. This combination of machines is perfect for maximising production in a restricted space, allowing the customer to handle a large volume of orders at impressive output speed in continuous motion with rapid and accurate changeovers between container and tray sizes.

The Result:

Our client was very happy with the whole process, including the FAT, the installation, and the commissioning. They were able to re-assign labour to other jobs and instantly increased their line efficiency. This increase in efficiency, together with the considerable cost savings the C-2000T machines are giving them, has meant they have retained their clients, beating out their competition. They are so delighted that they are currently looking at automating other packaging processes within their factory.

- 2 manual packing lines replaced by a single high-speed automated packaging line

- Increased operational speed

- Decreased changeover time

- Maximised best use of available space

- Reduced 66% of labour costs

The compact layout of the packaging line has proved so successful that the customer is now considering automating two other packaging lines within the same area.