Grace Foods have ordered another Pneumatic Tray Erector from WestRock PMA Packaging Systems this time with extended height to suit their existing factory line.

WestRock PMA have adapted the height of their standard Pneumatic Tray Erector to suit Grace Foods’ existing factory line. The machine has been modified to include an extra plinth which raises the machine height to comply with the company’s tall one meter conveyor height. After the success of the WestRock PMA VE500 Pneumatic tray erector, which was installed into Grace Foods in 2015, Grace didn’t hesitate to choose WestRock PMA again. Grace’s new Tray Erector, the TFP500, is the next generation VE500 making it completely compatible and ideal for side by side production.

Grace Foods is one of the UK’s favourite manufacturers of Caribbean food and drink. The company distribute a diverse and authentic range of products around the UK including, sauces, tropical drinks, and a range of Caribbean recipes.

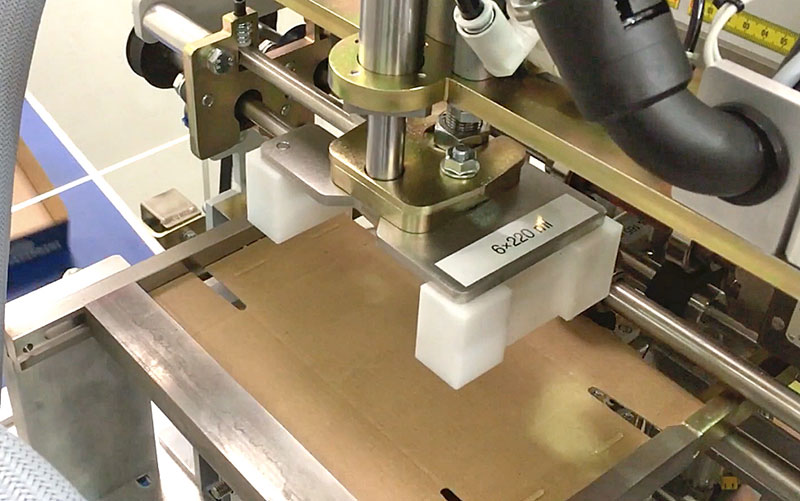

The WestRock PMA machine has been designed to erect small trays of three varying sizes, to suit Grace Foods’ range of exotic spices. The trays are erected by a pneumatic ‘puncher’ maximising the machines speed.

The TFP500 Tray Erector, which has been installed into Grace Foods, is a high performance tray erector machine which can run at speeds of up to 24 trays per minute and seals trays with an Italian Preo glue system.

After the success of the WestRock PMA VE500 Pneumatic tray erector, which was installed into Grace Foods in 2015, Grace didn’t hesitate to choose WestRock PMA again. Grace’s new Tray Erector, the TFP500, is the next generation VE500 making it completely compatible and ideal for side by side production.

Grace Foods is one of the UK’s favourite manufacturers of Caribbean food and drink. The company distribute a diverse and authentic range of products around the UK including, sauces, tropical drinks, and a range of Caribbean recipes.

The WestRock PMA machine has been designed to erect small trays of three varying sizes, to suit Grace Foods’ range of exotic spices. The trays are erected by a pneumatic ‘puncher’ maximising the machines speed.

The TFP500 Tray Erector, which has been installed into Grace Foods, is a high performance tray erector machine which can run at speeds of up to 24 trays per minute and seals trays with an Italian Preo glue system.

WestRock PMA Pneumatic Tray Erector has three tray size capabilities with easy changeover technology.