WestRock PMA in partnership with Elesa, install accurate machine set up system and increase efficiency

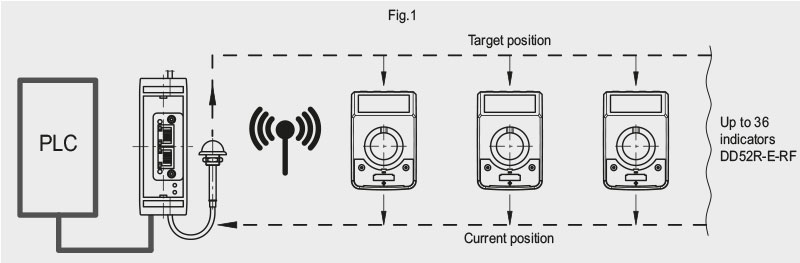

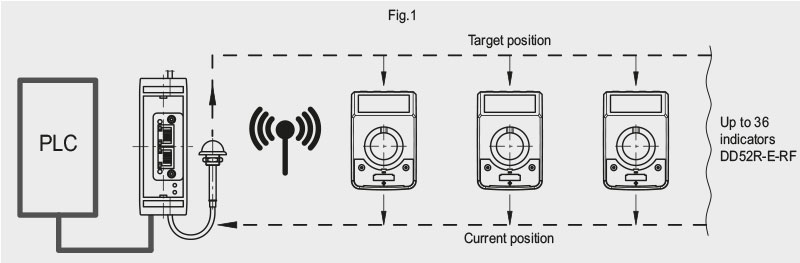

The Elesa wireless spindle positioning system enables faster and more reliable machine set up by use of a wireless connected profile controller, which displays the initial set up values on each of up to 36 electronic position indicators.

WestRock PMA Systems can install the new Wireless spindle positioning indicator system to new machines or retrospectively as an upgrade to compatible PLCs.

Sean Dunne, Unilever comments, “this cost-effective upgrade was added to our machines in under 2 days, and has already made huge improvements to product change overs and set-up times”

View testimonial ‘Unilever Ice Cream Wireless Positioning Project’

WestRock PMA Elesa wireless spindle positioning indicator system overview

The operator can simply choose the appropriate recipe then quickly re-set each wifi spindle to its correct position and the machine is “good to go”.

This saves time and takes out much of the possibility of human error.

Actual and target positions are transmitted by RF to and from the control unit, facilitating rapid machine set up.

The operator manually sets the position of the spindles following the arrow displayed on the LCD (clockwise/counter-clockwise rotation).

Once all the spindles are correctly set, the UC-RF control unit communicates to the PLC of the machine that the setup has been completed – the system prevents the start of the machine until the set-up has been completed, for machine safety reasons and to prevent loss of production from incorrect settings.

The UC-RF controller can network with up to 36 position indicators and is compatible with PLC Interfaces: RS232, RS485, Ethernet/IP, Profibus and Modbus. The DD52R-E-RF (IP67) position indicator 6 digit display mode can be selected by the operator.

Actual and target positions are transmitted by RF to and from the control unit, facilitating rapid machine set up.

The operator manually sets the position of the spindles following the arrow displayed on the LCD (clockwise/counter-clockwise rotation).

Once all the spindles are correctly set, the UC-RF control unit communicates to the PLC of the machine that the setup has been completed – the system prevents the start of the machine until the set-up has been completed, for machine safety reasons and to prevent loss of production from incorrect settings.

Actual and target positions are transmitted by RF to and from the control unit, facilitating rapid machine set up.

The operator manually sets the position of the spindles following the arrow displayed on the LCD (clockwise/counter-clockwise rotation).

Once all the spindles are correctly set, the UC-RF control unit communicates to the PLC of the machine that the setup has been completed – the system prevents the start of the machine until the set-up has been completed, for machine safety reasons and to prevent loss of production from incorrect settings.

The UC-RF controller can network with up to 36 position indicators and is compatible with PLC Interfaces: RS232, RS485, Ethernet/IP, Profibus and Modbus. The DD52R-E-RF (IP67) position indicator 6 digit display mode can be selected by the operator.

The UC-RF controller can network with up to 36 position indicators and is compatible with PLC Interfaces: RS232, RS485, Ethernet/IP, Profibus and Modbus. The DD52R-E-RF (IP67) position indicator 6 digit display mode can be selected by the operator.