The machines prepare products so that they can be delivered to a retailer in a ready-to-sell merchandised unit, making them easy to place on the shelf without the need for unpacking or repacking for optimum sustainability.

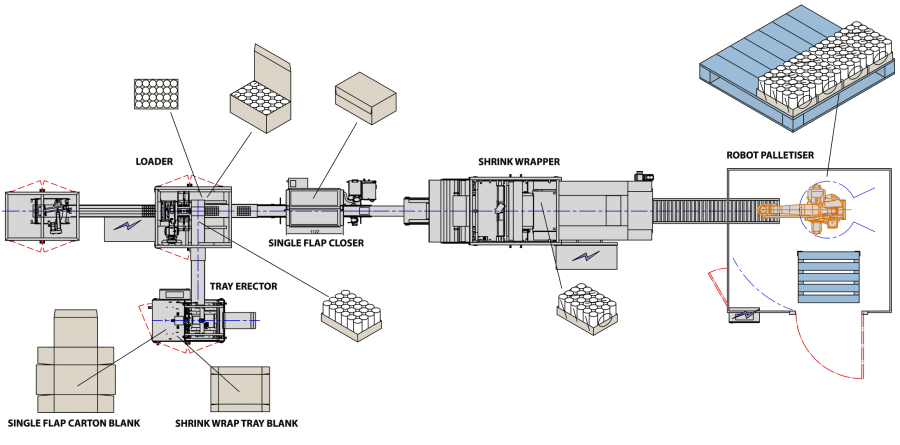

Among the many modules that can be combined to produce standard customised shelf-ready packaging (SRP) solutions are carton/tray erectors with an output of up to 100 trays per minute, carton sealing/closing units to suit almost any type of carton, carton/tray loaders, and semi-automatic or manual loading shrink wrappers.

Our shelf ready solutions can also include robotic loading case and tray loading, robot palletisers, which have been developed specifically for use in modern retail ready production environments, and gantry palletisers that combine the benefits of small footprint, low cost and high operation speed with rapid return on investment. Both types of palletiser have potential for convenient and cost-effective future expansion.

View our range of automated packaging machinery: Erecting | Collating | Loading | Closing | Wrapping | Palletising

A typical automated WestRock Packaging Machinery & Automation Shelf Ready Packaging (SRP) Retail Ready Packaging System Schematic