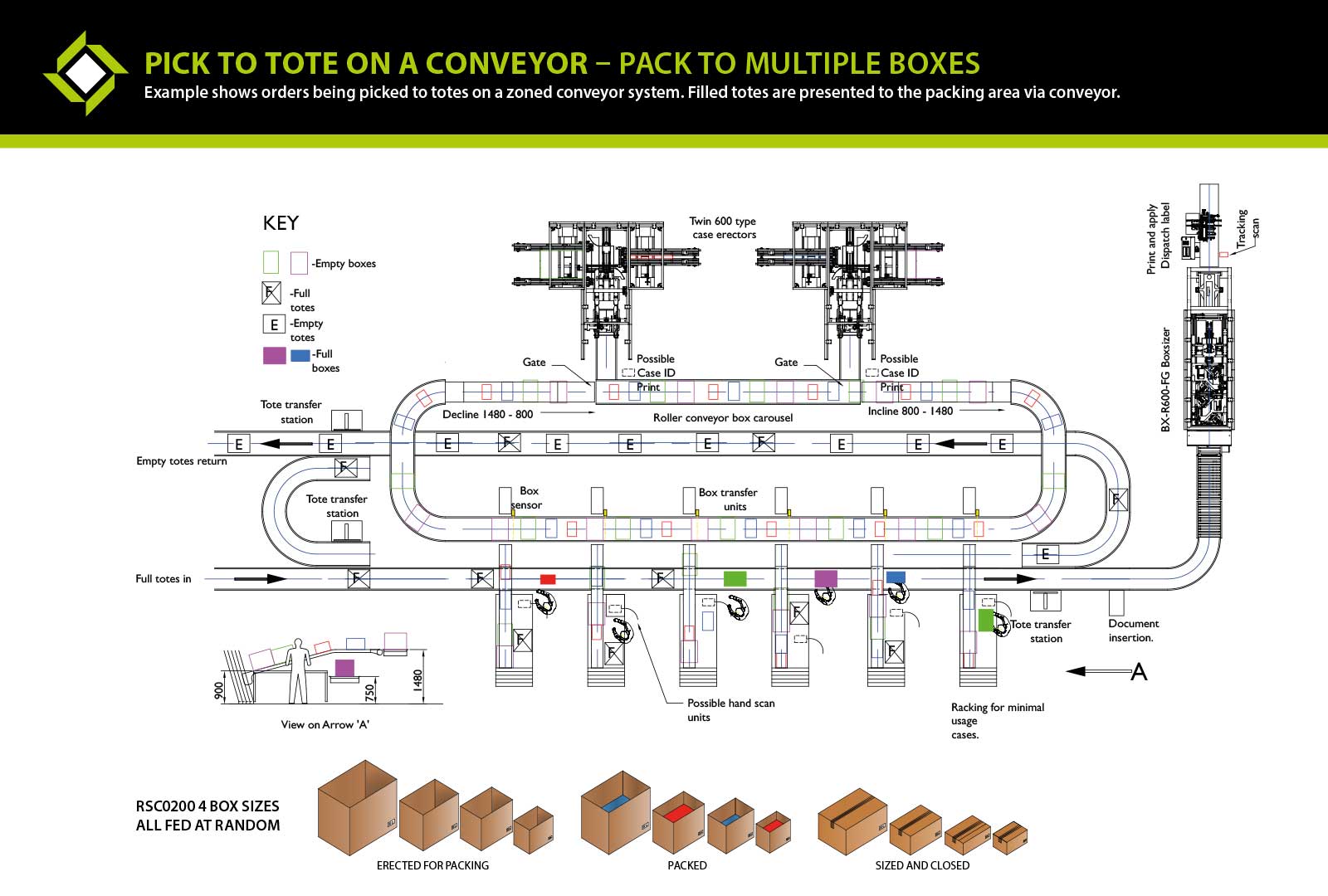

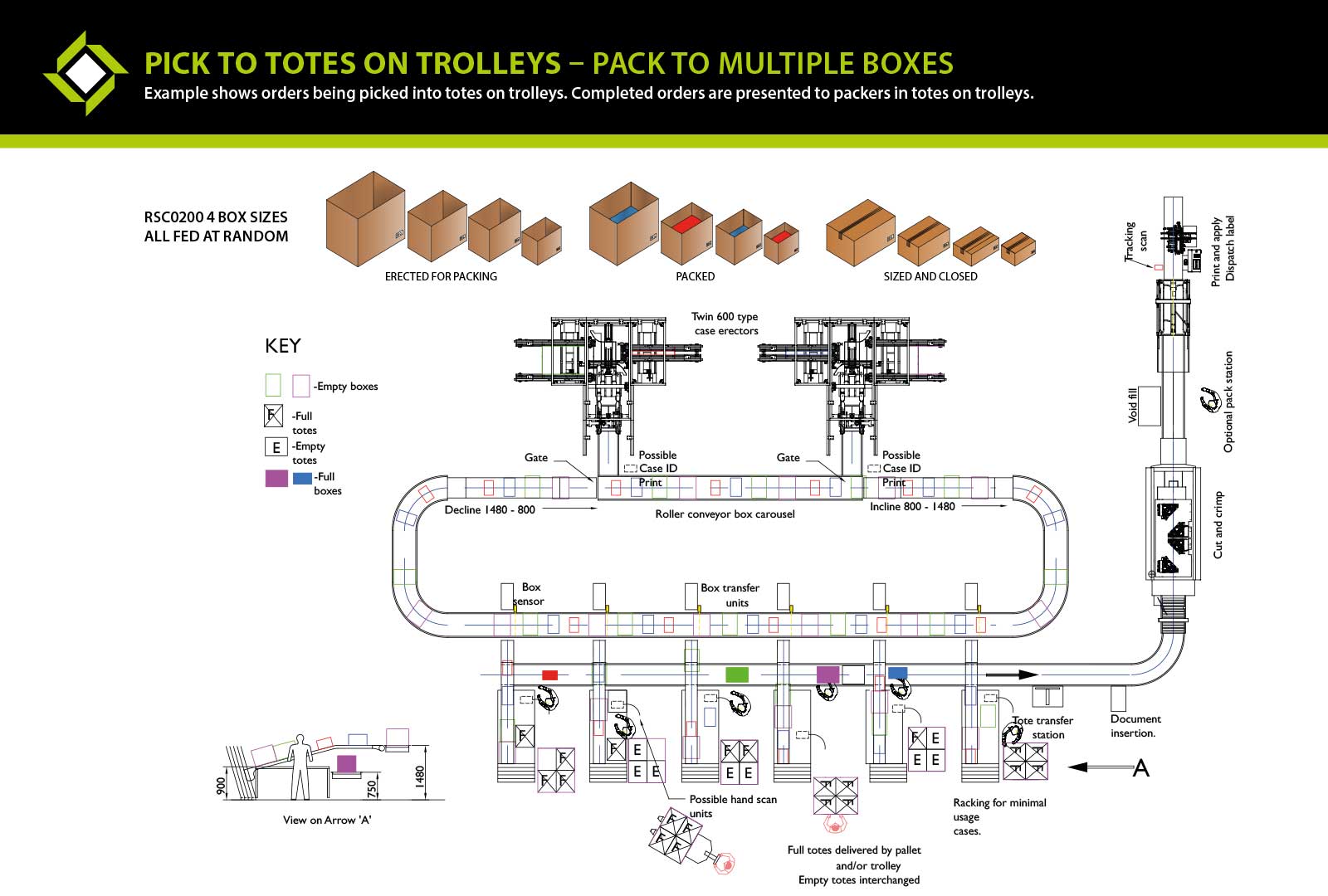

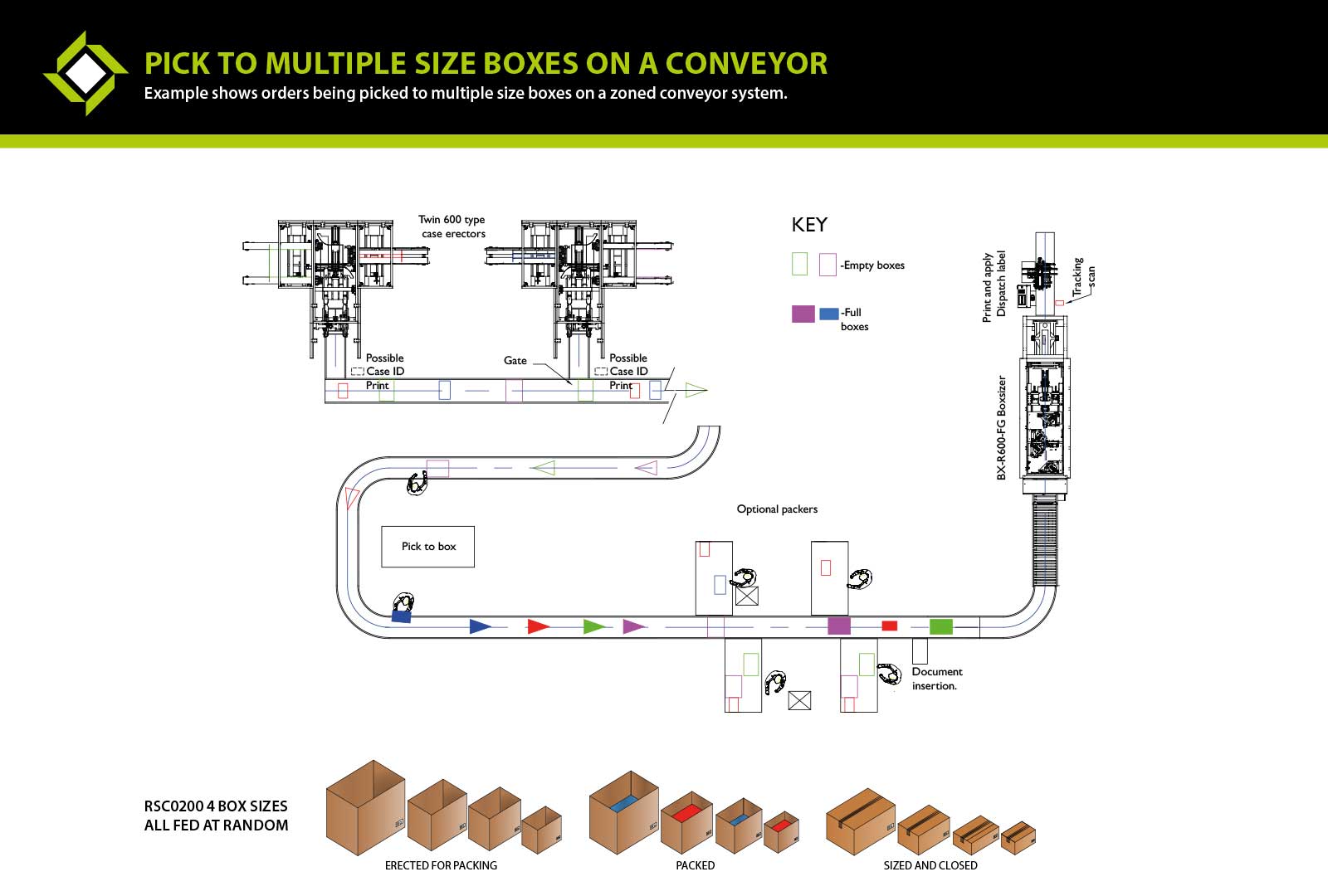

Boxsizer® is our flagship model, it is a smart case closer, that intelligently down sizes loaded boxes to reduce any empty space, void fill, materials, labour and shipping costs.

Boxsizer® was designed specifically for warehouse dispatch automation and the ever increasing eCommerce market.

Our multi-award winning Boxsizer® is the only stand-alone smart packaging Warehouse Dispatch Automation machine that automatically downsizes multiple footprint boxes, reduces packaging and volumetric dimensional weight (DIM weight), saves on Labour, Materials and Transportation costs.

- SAVE ON TRANSPORT COSTS

- SAVE ON MATERIAL COSTS

- FUTURE PROOF YOUR DISPATCH

- SAVE ON LABOUR COSTS

- SAVE ON INVESTMENT COSTS

- FUTURE-PROOF YOUR OPERATIONS

- REDUCE CARBON FOOTPRINT

- SMART FACTORY – INDUSTRY 4.0 READY

Boxsizer® Warehouse Dispatch Automation maximises cost savings year-on-year, proven typical savings are:

30% average volume reduction,

80% reduction of excess packaging infill and

50% typical reduction in required labour. Typical ROI is 6-12 months, based on dispatch volumes of 1 million boxes per year.