How WestRock PMA Case Erecting Machines make Square Cases Everytime

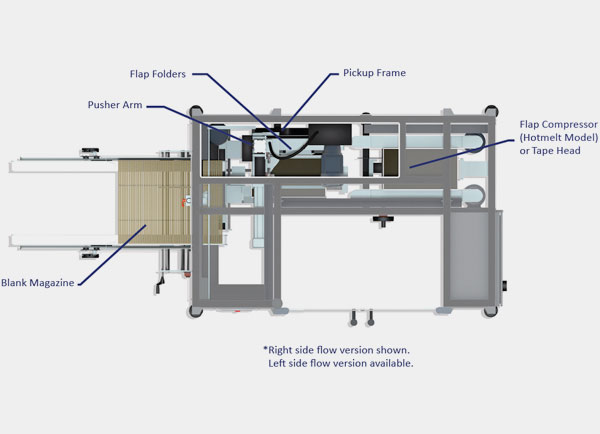

From the moment a blank enters the magazine until it exits the case erector as a properly formed and bottom sealed case, it is under complete control.

A unique pickup frame pulls the case from the magazine and forces it to open so it is square. The flaps are folded before the case moves, making it rigid and locking in its “squareness”.

A pusher bar, parallel to the rear wall, delivers it to spring-loaded side belts, which move in or out to compensate for variations in width, and carry it over the sealing device.