Robot Collators and Loaders

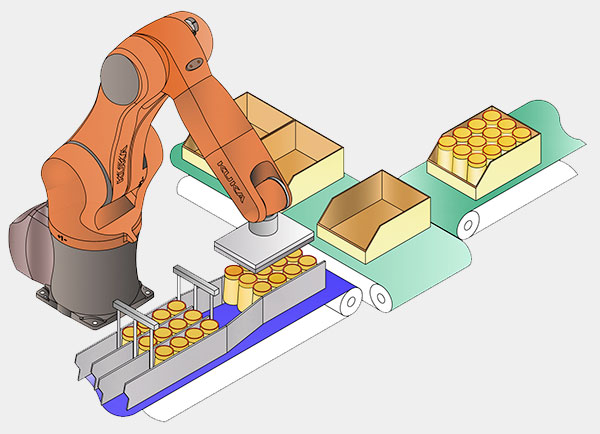

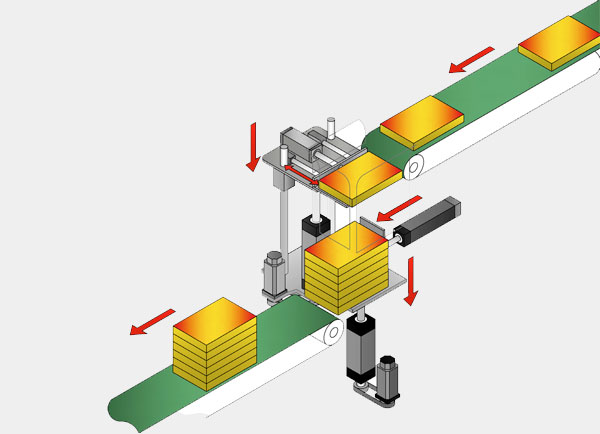

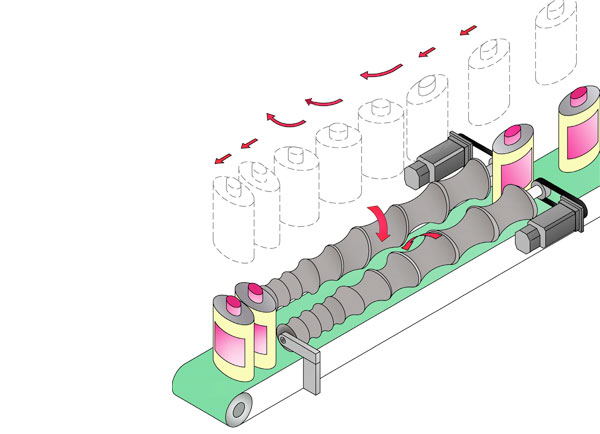

Our Robot Collators and Loaders allow you to automatically pack product into pre-erected, lined or unlined corrugated trays or cases. With a robotic palletiser your product can be stacked in any orientation, within your container, allowing for fully automated shelf-ready packing and reduced supply chain costs.

Due to the continuous motion of robot collators and loaders there is no need for an operator, reducing labour and maintenance costs as well as health hazards. The user interface is friendly allowing for quick and repeatable size changes.

The WestRock PMA Systems Robotic Carton Loaders are fully adjustable and upgradable. KUKA’s precise, 6 axis servo-controlled automatic tool change over and interchangeable tooling, gives the robotic machine flexibility, over the original tray/case packer, to handle multiple product sizes. The adjustable pick and place tools allow for accurate product placement every time. Our robot collators and loaders have a compact footprint allowing for an efficient usage of floor space.

Robot Collator Loader

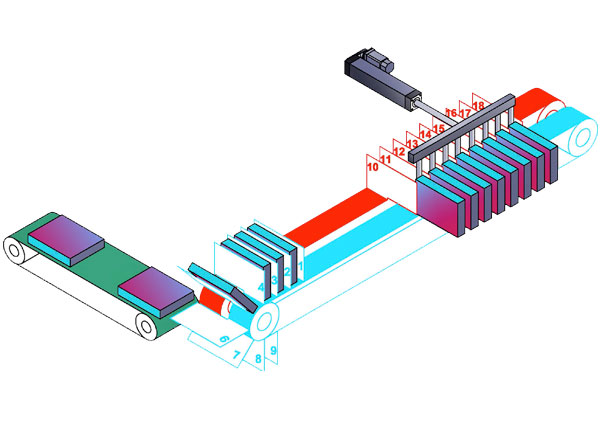

STANDARD TECHNICAL SPECIFICATIONS

- Speed: Up to 200 CPM (dependant on product and product format)

- Concept: Multiple sizes

- Robot: KUKA robot to suit application

- Operating height: 900mm nominal

- Sample Power Consumption: 11.5Kw, 24.5A/Ph, 440V, 3 Phase, N & E

- Air Supply: Dependant on pickhead type

- Net Weight: Dependant on robot type

- Specific Components: Rockwell Controls, SMC Pneumatics

- Colour: RAL 9007 Grey (except for robot)

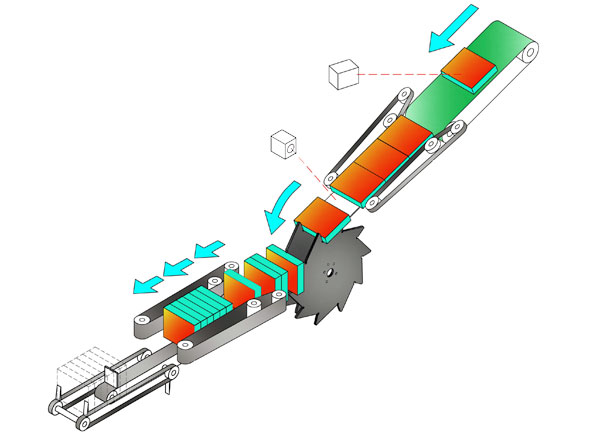

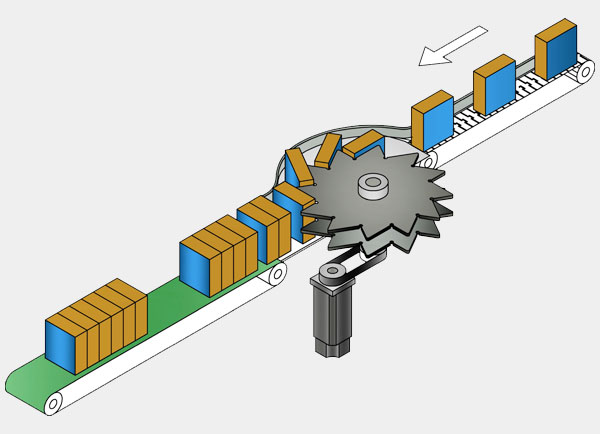

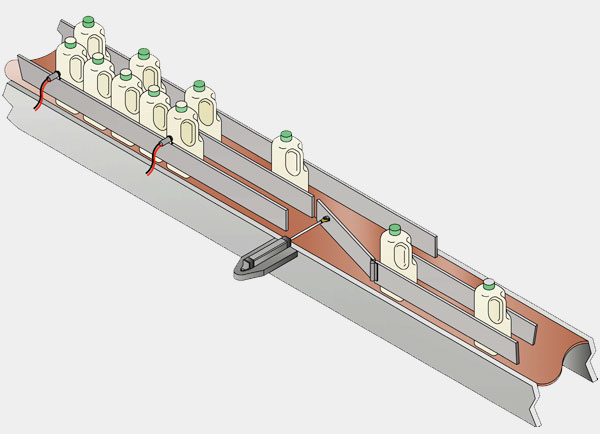

PACK TYPE